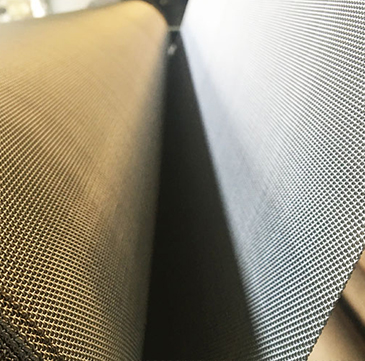

Standard Five-layer Sintered Mesh Price in Peru: Understanding Its Components and Working Mechanisms Sintered mesh technology has been a game-changer in modern manufacturing, revolutionizing various industries such as the pharmaceutical, food, and chemical sectors. Peru is no exception, with a growing demand for Standard Five-layer Sintered Mesh price for its excellent filtration and separation capabilities. This article aims to delve into how Standard Five-layer Sintered Mesh price works and its key components. How Standard Five-layer Sintered Mesh Price Works Standard Five-layer Sintered Mesh price has five distinct layers consisting of support, filter, protective, and two diffusion layers. The first layer, support, provides mechanical strength to the mesh, while the second and third layers are the filter layers that trap particles based on size and structure. The fourth layer is the protective layer that shields the mesh from external factors such as corrosion, temperature, and pressure. Finally, the fifth layer is the diffusion layer that helps distribute gas or liquid through the mesh evenly. Standard Five-layer Sintered Mesh price in Peru has a unique manufacturing process that involves compressing and heating metal powder at high temperatures to form a solid and robust mesh. This advanced technology not only ensures uniform distribution and high precision but also allows for customization based on client specifications. Application and Importance of Advanced Technology The advanced technology used in Standard Five-layer Sintered Mesh price in Peru has many benefits for modern manufacturing. It enables the production of specialized and customized filters that meet specific industry requirements, thus increasing efficiency and reducing waste. Additionally, the sintering process ensures a strong and durable mesh, leading to reduced maintenance costs and longer-lasting filtration systems. Moreover, with the increasing demand for eco-friendly manufacturing processes, sintered mesh technology offers energy-efficient filtration solutions that conserve resources. Practical Applications and Scenarios Standard Five-layer Sintered Mesh price in Peru has various applications in different sectors, such as gas filtration in power plants, wastewater treatment, and oil and gas refining. For instance, in the pharmaceutical industry, sintered mesh technology is essential in the production of drugs as it ensures the removal of impurities and contaminants from the raw materials. Similarly, in the food processing industry, filtration systems that use sintered mesh technology facilitate a clean and hygienic production process. Conclusion In conclusion, Standard Five-layer Sintered Mesh price in Peru is an essential component of modern manufacturing. Its unique design and advanced technology ensure efficient production processes and high precision, leading to higher productivity and reduced costs. If you are looking for reliable Standard Five-layer Sintered Mesh suppliers in Peru, contact us for high-quality and customized solutions to suit your filtration needs. Keywords: Contact us, Suppliers.