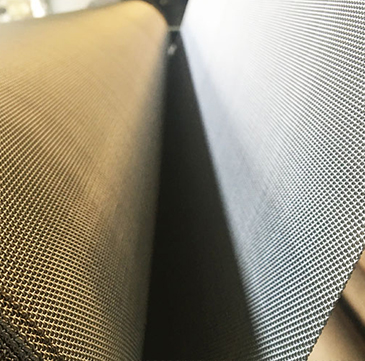

Understanding the Standard Five-layer Sintered Mesh Price in Denmark Sintered mesh technology is at the forefront of modern manufacturing. Standard five-layer sintered mesh, in particular, is a highly sought-after product in Denmark. Its popularity comes from the fact that it is a versatile, durable, and high-performance solution in many industrial applications such as filtration, fluidization, and gas diffusion. The system works through a complex sintering process that creates a series of interlocking, uniform pores throughout the mesh. The five-layer aspect of this mesh system allows for both a high degree of filtration and excellent flow rates. The key components of Standard Five-layer Sintered Mesh include the mesh material, sintering process, and sophisticated machinery for cutting and shaping the final product. Manufacturers employ advanced technology to ensure consistent, high-quality production of Standard Five-layer Sintered Mesh. High-temperature vacuum sintering presses the layers together to produce a mesh that is stronger and more uniform than traditional woven wire mesh. The sintering process allows for multiple layers of mesh to be formed together, offering a diverse range of filtration options to fit a variety of industry needs. Standard Five-layer Sintered Mesh is applicable in various scenarios, including chemical processing, pharmaceuticals, water filtration, and oil and gas. For instance, it can be used in water treatment plants to filter impurities from water before it is distributed to homes and businesses. It is also effective in food processing industries, where it can be used to ensure that food products are free of contaminants. The advanced technology used in the production of Standard Five-layer Sintered Mesh is vital to ensure efficient and consistent manufacturing at scale. This means that the production process is efficient, reducing waste and costs while giving end-users a competitive advantage. In conclusion, Standard Five-layer Sintered Mesh is an essential component of modern industrial applications. The sintering process, advanced machinery, and high-level precision involved in its production make it an efficient and cost-effective solution for various industries. For any inquiries or to discuss your mesh requirements, contact us for more information on suppliers and pricing.