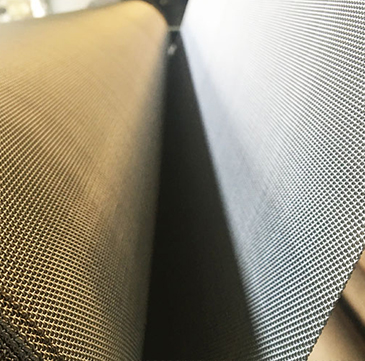

How Standard Five-layer Sintered Mesh Works in Brazil Standard Five-layer Sintered Mesh is a vital element in modern manufacturing processes in Brazil. It is a high-performance metal filter media consisting of five different layers of sintered wire mesh. Each layer has a different mesh size and shape, providing enhanced strength, precision, and stability. The key components of Standard Five-layer Sintered Mesh include a support layer, filter layer, protection layer, and two diffusion layers. The support layer provides stability and strength to the mesh, while the filter layer captures and retains solid particles and impurities from fluids. The two diffusion layers facilitate the flow of fluids and gases. The working mechanism of Standard Five-layer Sintered Mesh is based on the principles of mechanical, physical, and chemical reactions. The mesh operates by filtering fluids and gases under high pressure, temperature, and corrosive conditions. The mesh allows fluids and gases to pass through the interconnected pores and channels, while retaining solid particles and impurities. Standard Five-layer Sintered Mesh is made possible by advanced technological processes and materials. These include precision laser cutting, ultra-high temperature sintering, and specialized welding techniques. The use of advanced technology enables efficient production processes, consistent product quality, and customization options for different applications. Standard Five-layer Sintered Mesh has numerous application scenarios in various industries, including the chemical, food and beverage, pharmaceutical, and oil and gas industries. The mesh is used in fluid filtration, gas distribution, powder handling, and gas diffusion. In oil and gas industries, the mesh is used for sand control and well completion. In conclusion, Standard Five-layer Sintered Mesh is an essential component in modern manufacturing processes in Brazil. It operates by filtering fluids and gases under high pressure, temperature, and corrosive conditions. Its efficiency is enabled by advanced technologies and materials. Practical application scenarios include fluid filtration, gas distribution, and sand control in oil and gas industries. Contact us for more information on suppliers and customization options for your specific needs.