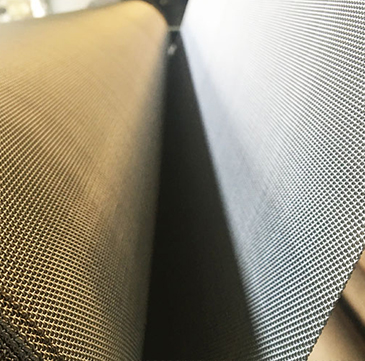

How Standard Five-layer Sintered Mesh Works in Modern Manufacturing Standard Five-layer Sintered Mesh is a high-performance filtration material used in various industrial and chemical applications. It comprises five layers of woven wire mesh, which are compressed and sintered to form a single, rigid structure. This article explains how Standard Five-layer Sintered Mesh price in United works, its key components, and working mechanisms. The Key Components of Standard Five-layer Sintered Mesh Standard Five-layer Sintered Mesh consists of five layers of woven wire mesh, arranged in increasing porosity from outer to inner layers. The outer layers are coarse, providing mechanical strength and protecting the finer inner layers from damage. The inner layers have smaller pore sizes, enabling efficient filtration of particles and contaminants. Working Mechanisms of Standard Five-layer Sintered Mesh Standard Five-layer Sintered Mesh works on the principle of depth filtration, wherein particles are trapped within the multiple layers of mesh. As the fluid passes through the mesh, larger particles get trapped in the outer layers, while smaller particles get trapped in the inner layers. The mesh structure forms a tortuous path, forcing the fluid to flow through numerous small channels, leading to efficient particle capture. Applications of Advanced Technology in Standard Five-layer Sintered Mesh Production Advanced technology plays a crucial role in the production of Standard Five-layer Sintered Mesh. Various manufacturing processes, such as laser cutting, welding, and CNC machining, enable precise and accurate fabrication of mesh components, resulting in consistent quality and performance. Furthermore, automated assembly and inspection processes enable quick turnaround times, reducing lead times and meeting customer demands. Practical Examples of Standard Five-layer Sintered Mesh Applications Standard Five-layer Sintered Mesh is used in several industrial and chemical applications, including petrochemical refining, pharmaceuticals, food and beverage processing, and wastewater treatment. For instance, in petrochemical refining, it is used in catalyst support systems, gas and liquid filtration, and steam stripping applications. In the pharmaceutical industry, it is used for sterile venting and final filtration of drugs and vaccines. Conclusion In summary, Standard Five-layer Sintered Mesh is a highly effective filtration material used in modern manufacturing processes. Its key components and working mechanisms enable efficient particle capture and removal, while advanced technology plays a crucial role in its production. Practical examples of its applications showcase its versatility and effectiveness in various industries and sectors. To learn more about Standard Five-layer Sintered Mesh, contact us for premium quality products and services from reputable suppliers.